What We Did

What We Did

- Website Copywriting

- Taglines

- Tradeshow

- Story Writing

Challenge

Challenge

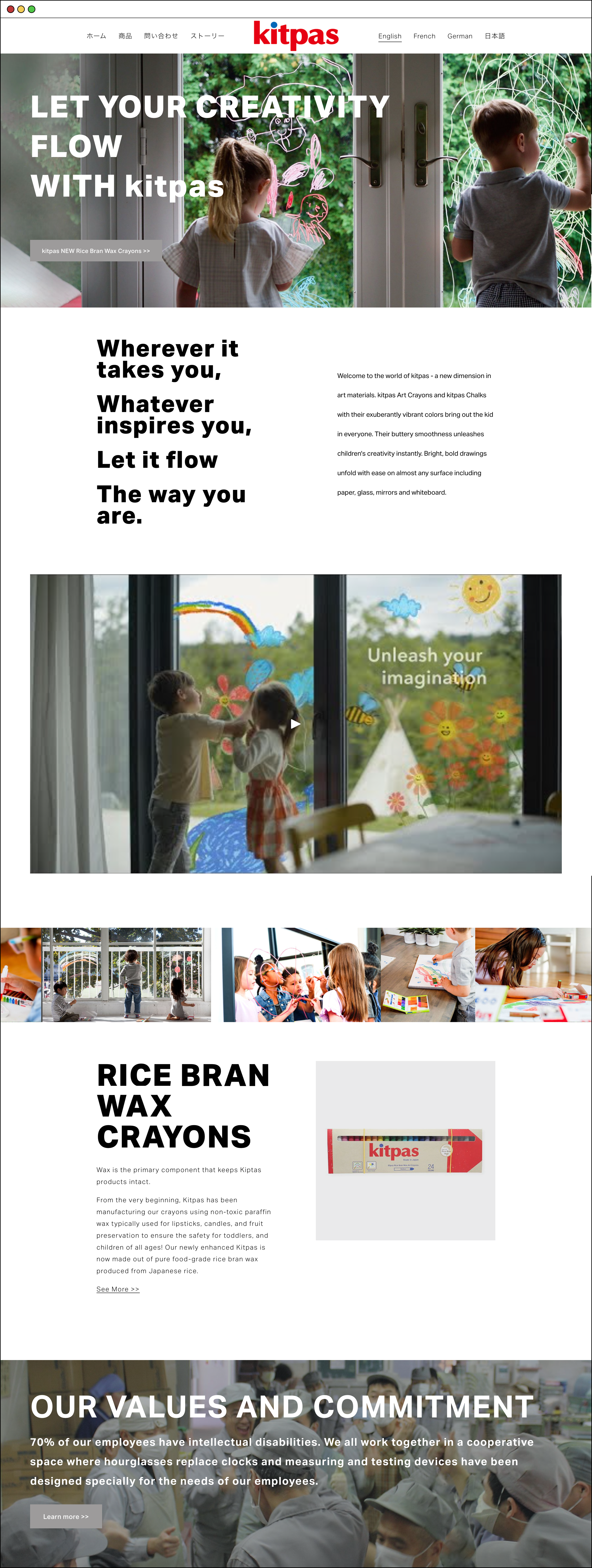

Kitpas makes high-quality art crayons made out of recycled rice bran, and chalks with recycled seashell powder from Hokkaido, Japan, with an intention of reducing waste in the Japanese seafood industry.

With many other competitors manufacturing art materials in the U.S., it was essential to communicate the distinctive qualities of Kitpas that differentiates from other brands.

Additionally, Kitpas offered a myriad types of art materials that needed to be categorized and clearly displayed its key features (sizes, colors, packs) through easy-to-follow product descriptions.

Execution

Execution

We identified the key strengths of their products and communicated the fact that the quality of their art materials are superior to most art materials available in the market. Beyond the quality of the products, we have developed an intensive story and mission statements that communicate their environmental and social mission of their company by gaining insights into Kitpas’s history and hiring values that defined the brand. With Kitpas, they utilized their products as a vehicle to give back to the community, and it was important for their customers to know that their purchase makes a difference.

Tradeshow

Tradeshows are not only the place to showcase the products, but also where you can gain direct insights from the buyers, demonstrate the products in-person, and share stories behind the brand. We helped to gather both their positive feedback from the prospect buyers, allowing Kitpas to integrate viable ideas for their marketing, sales, and product development initiatives.

Storytelling

Through the discovery process with Kitpas, we identified one of their core stories that had not been told. In 1960, Kitpas hired their first 2 employees with intellectual disabilities. Since then, they have adapted their manufacturing method and work environment to fit the needs of the workers with different abilities. Currently, 70% of their full-time employees have disabilities, working collaboratively and safely in a space where hourglasses replace clocks, and measuring devices have been redesigned to simplify the manufacturing process.